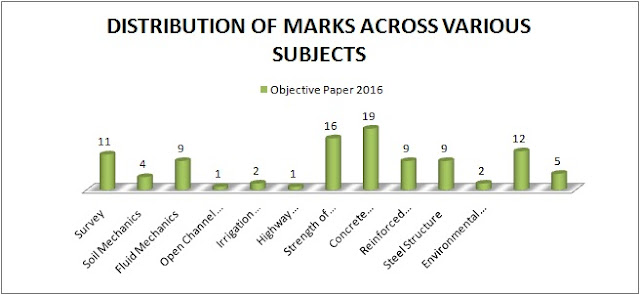

SSC JE MARKS DISTRIBUTION ACROSS VARIOUS SUBJECTS IN OBJECTIVE PAPER OF 2016

We would like to welcome all the visitors who are currently reading this. Efforts are once again being made to analyse the objective paper of SSC Junior Engineer Exam 2016. Same efforts was also made for the objective paper of SSC JE 2012 but after that such efforts were not made by the Admin Team due to the various constraints.

SSC JE 2017 is scheduled on 23 to 25 Dec 2017 and you all must be trying your level best to achieve the required cutoff percentage. For those, who have completed all the subjects already, it will be very easy to crack the exam. But still few peoples must be trying to cope up the time, which had been wasted by them. As we also belong to the second category of students, so we have an idea of their requirements. ☺

An analysis has been carried out by the Admin team for the objective paper of 2016. It is a well understood fact that pattern of paper remain more or less same so this type of marks distribution will help the students in prioritizing the subjects.

Hope it is going to help you to either begin from the scratch or improve your position if you are already in the race.

Please comment and share if enjoyed the post and content. Author will be highly indebted of your kind gesture.

SSC JE 2016 MARKS DISTRIBUTION ACROSS VARIOUS SUBJECTS IN OBJECTIVE PAPER.

S.No.

|

Subject

|

Marks

|

1

|

Survey

|

11

|

2

|

Soil

Mechanics

|

4

|

3

|

Fluid

Mechanics

|

9

|

4

|

Open

Channel Flow

|

1

|

5

|

Irrigation

Engineering

|

2

|

6

|

Highway

Engineering

|

1

|

7

|

Strength

of Material

|

16

|

8

|

Concrete

Technology

|

19

|

9

|

Reinforced

Cement Concrete

|

9

|

10

|

Steel

Structure

|

9

|

11

|

Environmental

Engineering

|

2

|

12

|

Building

Material & Construction

|

12

|

13

|

Estimation

& Costing

|

5

|

Few Points to Ponder :-

1. Survey :- Although majority of Questions asked were directly from Gupta and Gupta but one question was also asked from Transition curves. Made Easy Notes will help in this regard.

2. Soil Mechanics :- Only 04 Questions were asked from this subject. It seems that this evergreen subject is loosing its charm. But from practical aspects too, soil mechanics is not a very important subject for the jobs where you have to majorly deal with the construction activities. But still you must focus on this subject.

3. Fluid Mechanics :- One question was asked from pressure flow in pipes. Such question are bit harder side as far as Junior Engineer is concerned. Rest of the questions were easy in nature.

4. Open Channel Flow :- Only one question was asked from open channel flow and that too from Hydraulic Jump.

5. Irrigation Engineering : Only 2 questions. Gupta and Gupta Level.

6. Highway Engineering ;- One Question from Geometrical Design.

7. Concrete Technology. : Questions were easy but you need to remember them. Level Gupta and Gupta.

8. RCC :- Total 09 Questions. Majority of them were based directly on the provisions of IS 456 :2000. One question was also asked from prestress losses.

9. Steel Structure : 09 Questions from rivets.

10. Environment : 02 questions. That too from air pollution only.

11. Building Material : Easy questions. You need to remember them. Gupta and Gupta will suffice.

12. Estimation and Costing : Total 05 Question. One from Contract terminology. Rest were easy in nature. Gupta and Gupta will suffice.

As of now I am terminating the post here itself but will enhance it further in coming one or two days by including the analysis of Objective paper of 2014 and 2015.

Please feel free to suggest anything related to the post and also kindly promote the blog by sending the link to your dear ones.

THANK YOU